Product

TTS keeps expanding the business relationship with

customers and partners around the world based on various global networks.

-

Roof Seal

Roof SealSecondary Seal

The secondary seal reduces evaporation losses from the primary seal and prevents rainwater or other contaminants from entering the stored product. The compression plate can be mounted on either horizontal or vertical roof rims and is designed to accommodate specific bolt spacing. Overlapping compression plates provide strong sealing pressure against the tank shell. The wiper tip is made of UV- and weather-resistant synthetic rubber, ensuring high sealing efficiency. The shunts comply with API 2003.

-

Roof Seal

Roof SealTube Seal

The tube seal consists of a liquid-filled tube, covered by a scuffband, and positioned directly on the stored product. The liquid inside the tube applies gentle pressure against the tank shell, eliminating the gap between the stored product and the seal. A scuffband made of nylon fabric with an abrasion-resistant polymer coating is placed against the tank shell to prevent surface wear. The scuffband is bolted at both the top and bottom, with its lower portion in contact with the stored liquid (product-mounted). The liquid-filled tube exerts hydraulic pressure outward, pressing the scuffband firmly against the tank shell to create an effective seal.

-

Roof Seal

Roof SealMechanical Shoe Seal (Scissor Type)

The spring-type mechanical shoe seal features a simple, cost-effective design. It is easy to install without the need for hot work, such as welding, while providing reliable sealing performance. The shoes are held in continuous contact with the tank shell and extend into the product by means of hanger arms. High-tensile stainless steel springs apply pressure to the shoe at both the upper and lower positions. A vapor membrane seals the vapor space between the shoe and the roof, isolating it from the atmosphere.

-

Roof Seal

Roof SealMechanical Shoe Seal (Counterweight Type)

The pantograph-type mechanical shoe seal is the most widely used design for external floating roof tanks. A series of overlapping metallic shoes form a continuous ring, which is pressed against the tank shell by a pantograph-type mechanical system. The counterweight assembly and arms maintain constant pressure, ensuring the shoes remain in firm contact with the shell. A continuous vapor seal covers the space between the shoes and the roof, isolating it from the atmosphere.

-

Roof Seal

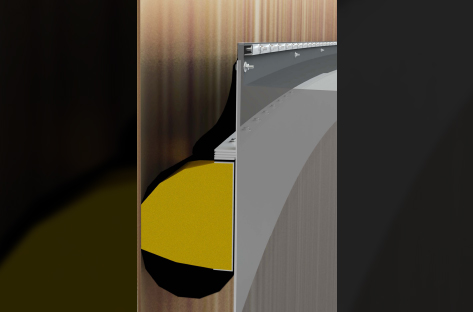

Roof SealFoam Seal (Vapor Mounted Type)

The flexible foam-filled primary rim seal consists of a series of foam blocks enclosed in an envelope and secured with steel plates. The foam blocks, compressed between the tank shell and the floating roof rim, provide highly efficient sealing performance. The TTS-FS5 Foam Seal is designed for both product-mounted and vapor-mounted types.

-

Roof Seal

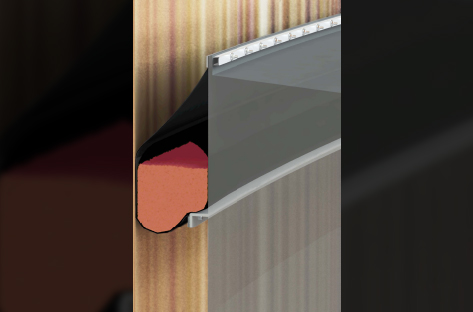

Roof SealFoam Seal (Liquid Mounted Type)

The flexible foam-filled primary rim seal is installed so that the bottom of the seal remains in contact with the stored product. The TTS-FS7 Foam Seal consists of a series of polyurethane foam blocks enclosed in an envelope and compressed between the tank shell and the floating roof rim, with the blocks secured by steel plates. This product-mounted type design eliminates the vapor space, while the curtain seal prevents vapors from passing between the roof and the metal frame or hanger bar.